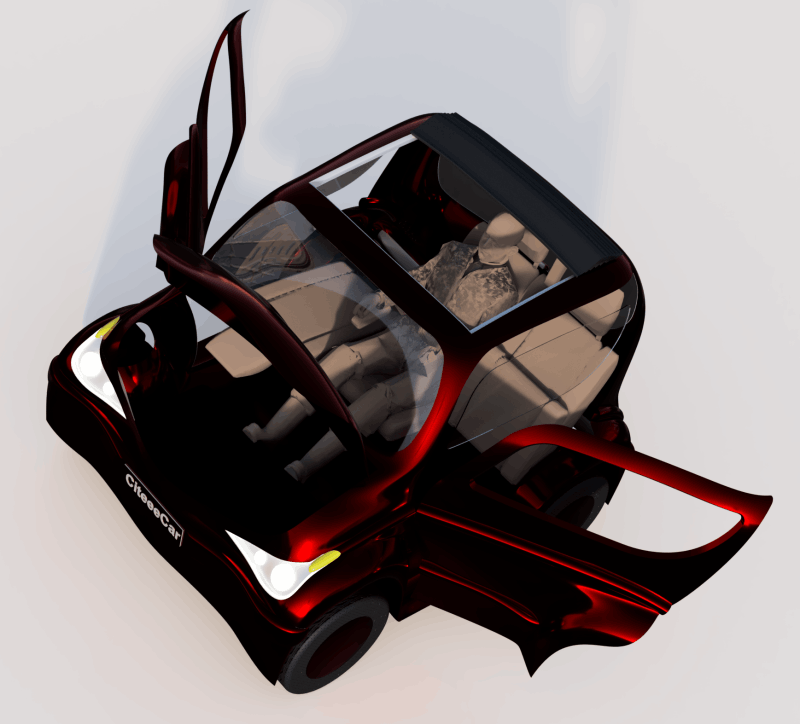

The first real citycar:

- a 3 seater (no tandem), ie. central position driving

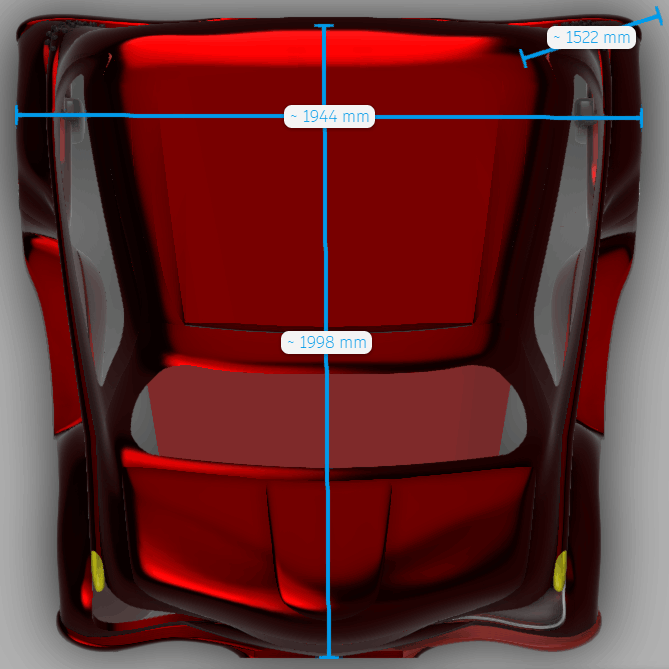

- can park perpendicular (really, not like a Smart)

- point-turns on one of the rear wheels

- no pedals, no steering wheel (patent registered)

- more driver-eye<>windshield distance than in a rolls royce

- 3 driver positions, ie choose the middle seat like formula one

- more luggage space than in a Smart

- 10kwh, 150km, 2x7.5kw wheel hubs = torque vectorisation

- cg a perfect 50/50

- offers a 1.8 x 1.4m inflatable queen size bed

- could be used as a city-utility vehicle (cuv for marketeers)

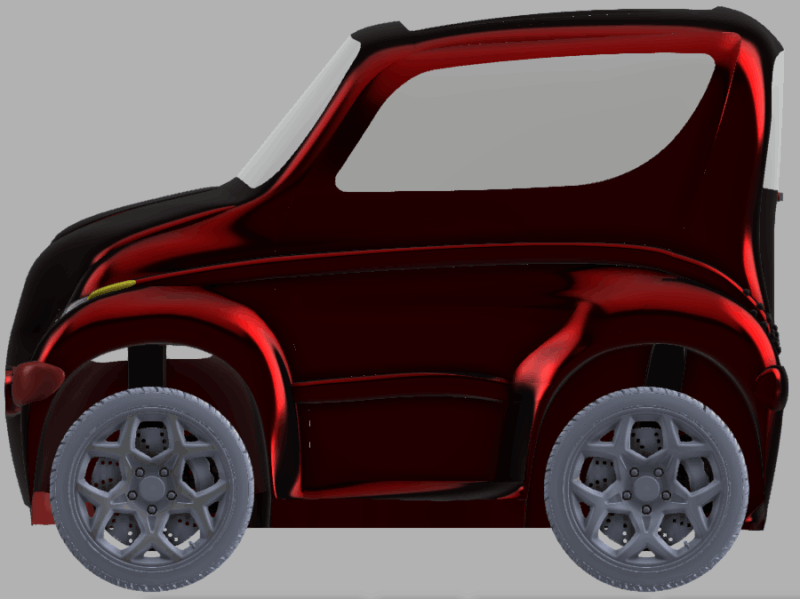

- sexy look, convertible, transparent rear-led & drl

- 100% customizable foil printing everywhere

- option: exchangable skin (as if you replace the cover of your mobile)

- great for individual public transport (to your door, not to nearest bus station)

so we created the individual public transport vehicle,

owned by the public community, as a door to door public transport system, or DDPT,

like an advancement ie from vélo bleu to voiture bleue in France.

It s a city car. As such it should only go 70km/h. depressed?

WAIT, now comes the best:

the car production: freeform-bent alu tube cage with inner and outer customer-defined pre-printed foils

this is a totally new technology of car manufacturing, like thermoforming, but in oil instead of air, enabling cycle rates of <5min per car, per line! (patent registered)

so if you want to produce a million cars a year, this is the perfect way to create such city cars in the next hyper-factory.

The idea for us is however to not build the cars ourselves, but to build the factories

The factory owners (investor groups or states) should be the car producers.

This way the Citeeecar can be produced in the millions, financed by multiple investors.

my idea is a total game changer: in future there is a producer of a product, and a producer of the production site.

the first will just care about raw material arriving just in time and delivery and marketing, branding, etc.

the latter produces the production machines and plans the factory and the product.

so every investor group or country can become an ie car producer, they just order the whole factory.

it s like a gigafactory2.0, and i call it the hyperfactory.

the clear interface between production site and product clarifies the respective responsabilities for maintenance and product development/modifications/customizations.

the factory owner doesnt need to plan/develop anymore, he already knows the ie car is working fine.

and the factory producer doesnt need to care about the manufactoring itself, he just creates the methods/machines,

he doesnt need to care about selling, nor does the producer need to care about product structure stability/crash test, design, machinability, floor plans, etc.

the factory producer gets further business if he can offer new ie cars. he finances the machines and factory parts only, so he can sell hundreds of factories.

and each ie citeeecar hyperfactory owner knows exactly his car output for his region he got exclusivity for.

this way hyperfactories with outputs between 0.1mio-10mio cars can be planned (all the same, just multiple lines parallel).

factories could be sold to an investor group, or leased to another, but for some countries it might be interesting for the factory producer to also produce and sell or rent out the product, ie the citeeecar, to the user, or just create income by participating in fares the passenger paid for the milage.

so "difficult" countries will be glad to create their own car industry, where others just want to reduce co2 no matter who s cars offer the best transport mix of community cars, private ownership renting out to portals like uber, yandex, etc, all that counts would be convenient transportation from door to door at the least cost to man and environment.

so that is the business idea in the end.

more info? Shoot me a line: markus@citeeecar.com more vids/docs/pics

Built with Mobirise - Go now